Reduced eco-footprint

The Arctic Paper mills are situated in beautiful natural areas, close to watercourses. Therefore, environmental concerns in regards to production and transportation has become our highest priority. Take for instance the Munkedal mill. As a consequence of our ecological thinking it is today one of the cleanest in the whole world.

The Munkedal mill is one of the cleanest in the whole world

Arctic Paper S.A. has a long-standing commitment to environmental sustainability. We are proud to offer recyclable products made mainly from renewable resources. We strive to minimize the negative impact of our production by adopting and encouraging sustainable practices throughout the entire supply chain. The ISO 14001 management system is in place in all of our mills and guides our environmental work. All certificates along with environmental data are available here on our website.

In our production process, we focus our environmental efforts in four main areas:

- Energy consumption

- Water consumption

- Waste

- CO2 emissions

Energy consumption – Saving energy

At Arctic Paper we continuously work towards reducing the energy we use in our processes. Today our average usage in all mills is within or below the levels prescribed by the EU standard, BAT (Best Available Technique).

Arctic Paper Grycksbo’s bio-fuel plant based on wood pellets produces the mill’s entire requirement of steam. Apart from the boiler itself, the plant includes a scrubber filter and a turbine to produce its own green electricity. The transfer to bio-fuels has resulted in an annual reduction of fossil CO2 with approx. 75 000 tonnes.

A recent investment will increase the energy supply produced by environmentally friendly hydropower at the Arctic Paper Munkedal mill with 100 %, while decreasing the use of externally sourced electricity.

Kostrzyn total energy consumption

710,786 MWh/year

2.61 MWh per tonne

Energy for the power plant at Arctic Paper Kostrzyn is sourced from a natural gas field.

Water consumption – Re-using and purification of water

Re-using water

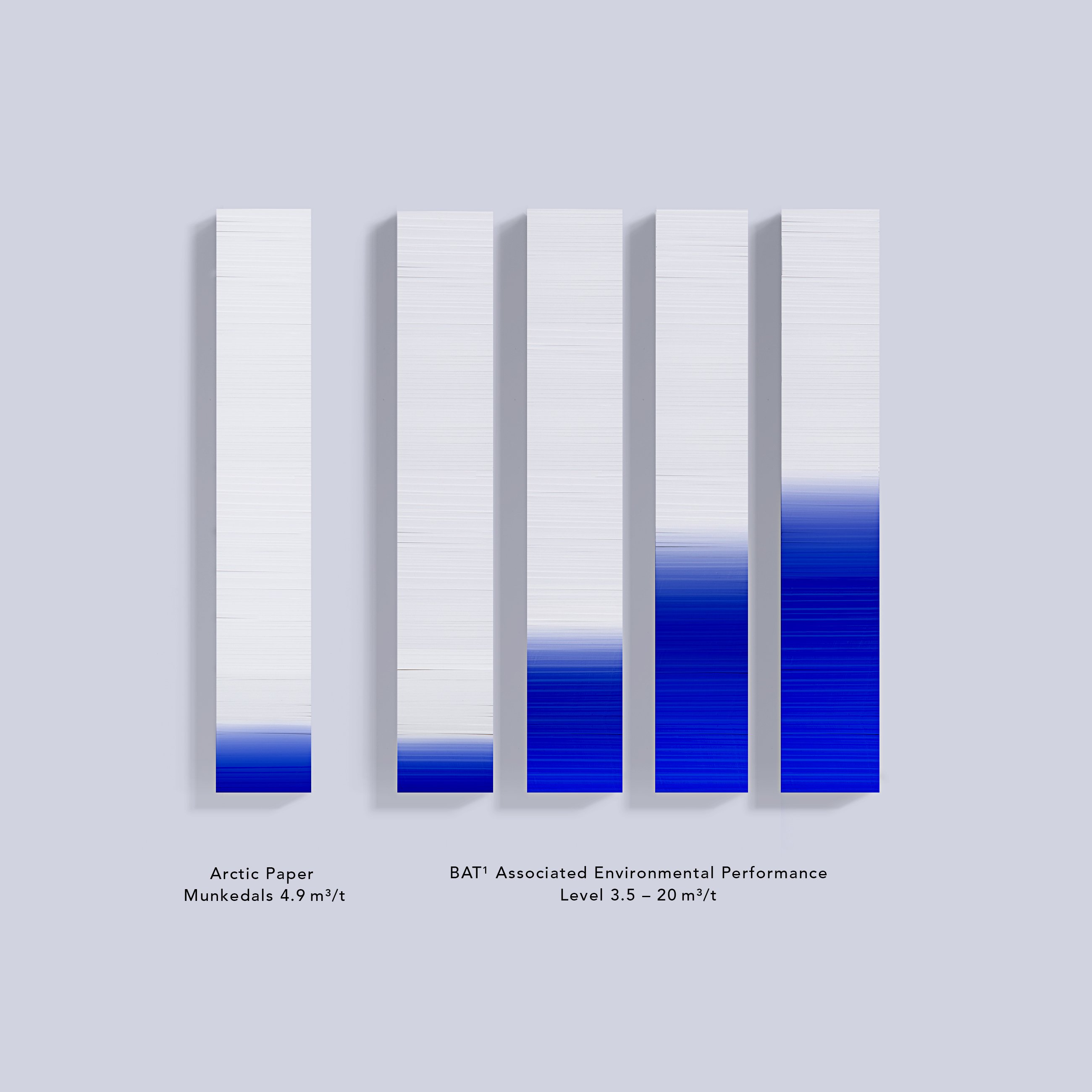

At Arctic Paper, we minimize water consumption by recycling large quantities of water. Our current water consumption throughout the Arctic Paper Group is, on average, less than 10 litres per 1 kg of paper. The mill at Munkedal uses 3-5 litres, one of the lowest consumption in the entire industry.

Purification of water

Protecting life in the local rivers is dear to the hearts of the people working in Munkedal. The discharge into water is among the lowest in the industry. At Arctic Paper Kostrzyn systems are in place for the effective purification of process water.

Waste – Handling waste and recycling

Handling waste

At Arctic Paper Munkedals, bio-sediment that fulfils the criteria for agricultural use is recovered, as soil improvement substrate, which creates a natural eco-cycle.

Recycling

To use our raw materials and energy as wisely and economically as possible, Arctic Paper has developed advanced systems for sorting and recycling materials and recovering energy from production waste.

CO2 emissions – Reducing the carbon footprint

Reducing the carbon footprint

Fighting global warming is one of our biggest challenges going forward. Luckily, paper production has a low impact on climate change, as growing healthy forests absorbs CO2. Even so, reductions of CO2 emissions from production and transportation of paper is one of the most important aspects of the environmental work at Arctic Paper.

A few examples of how we have managed to reduce the carbon footprint:

- The energy production process at Arctic Paper Grycksbo is totally carbon-neutral – thanks to the use of bio-fuel (wood pellets) that generate energy and heating. There are in other words zero emissions of fossil CO2 in this process, which is a key benefit when buying the paper brand G, produced at the mill.

- The Arctic Paper Grycksbo mill has also reduced CO2 emissions from the transportation of paper with more than 40 % by using carriers more efficiently, choosing railway transportation when possible and reducing transport distances.

- At the Arctic Paper Kostrzyn mill, huge investments in modern and efficient energy solutions have been made. The improved power plant, running on natural gas, which is much cleaner than oil and coal, has reduced CO2 emissions from paper production with more than 50 %. Today the mill is self-sufficient in energy for heating and electricity.

- The Arctic Paper Munkedals mill has signed a 15-year contract for the installation and operation of a waste/bio boiler plant with a capacity of 30 MV. This will ensure lower, stable and predictable energy costs with a 60 % reduction in CO2 emissions.